Are you facing difficulties in understanding Teflon PCB? Or you are wondering what makes them stand out in the realm of printed circuit boards? You are not alone as understanding the electronic components can be overwhelming, especially for a beginner.

But fear not as this article is here to help you understand what is Teflon PCB. We will also discuss its unique properties, explore its applications, and unravel key design considerations.

So, let’s get started.

What is Teflon PCB

As we all know, the Printed Circuit Board is the heart of electronic equipment, the only current-carrying conductor among the rest of the elements. But what is Teflon PCB?

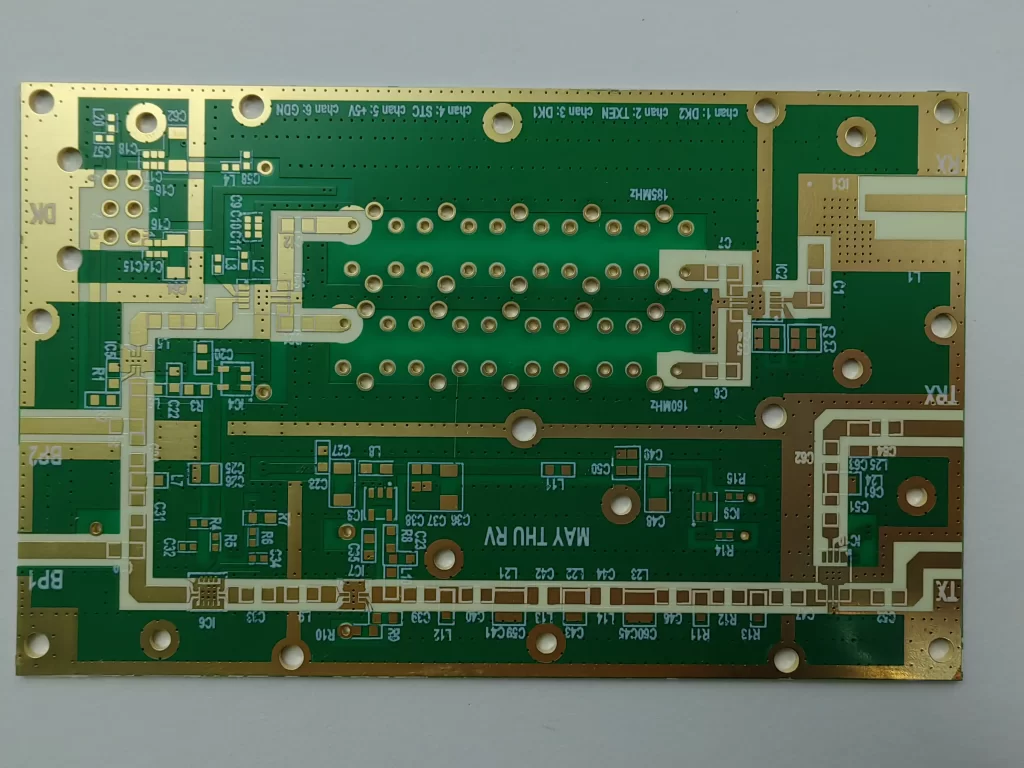

Well, Teflon PCBs are fabricated uniquely with the Teflon or Polytetrafluoroethylene or PTFE material in the PCB arena, which has etched a name for itself. Its astonishing properties make Teflon different from other materials.

First and foremost, its superior chemical resistance ensures protection against the corrosive influences of aggressive substances, hence giving the best solution for open environments that are exposed to a profusion of chemicals and solvents.

Furthermore, Teflon performs under comprehensive limits of temperature range, whereas its applications maintain their efficiency even up to limits of extremely high temperatures.

This is the property that makes it suitable for use in many operations at high temperatures. This will, in turn, mean that electronic devices are ready to operate under challenging conditions.

To be more specific, the critical reason why Teflon is an extremely attractive material is that it has a very low friction coefficient. It is the cause of less wear of components and, therefore, very supportive in any application where there is movement.

Let’s discuss how these properties make Teflon PCBs ideal for different applications.

Properties of Teflon (PTFE) for PCBs

The unique properties of Teflon make it particularly suited for specific applications.

Here’s how:

1.Chemical Resistance

The excellent chemical resistance of Teflon ensures the survival of PCBs in the harsh environment laden with chemicals, solvents, and oils. In industries like chemical processing and oil refining, where exposure to corrosive substances is inevitable, Teflon PCBs stand tall, ensuring longevity and reliability even amidst challenging conditions.

2.High-Temperature Performance

Teflon also holds an extraordinary place in the PCB field because of its high thermal tolerance. In this aspect, Teflon boards manage pretty well with constant heat-generating applications in industrial processing and automotive systems, among others. This ensures not just restricted downtime but also dramatically increases the lifespan of electronic devices in hostile environments.

3.Low Dielectric Constant

Although the low dielectric constant of Teflon may be highly promising for high frequencies, definite limits should be understood. This is given as a fact of nature—of advantage in some cases, such as signal integrity in a high-speed communication system. But its use for a real advantage will require the designer to be very cautious about whether or not to take advantage of a low dielectric constant for that particular frequency or application.

4.Low Friction Coefficient

It has a low friction coefficient, and this is good because it is used in most of the applications under movement where work is desired to be done without friction so that it will not damage the components. While its benefits are undeniable, it’s essential to acknowledge its limited use in certain scenarios. Nevertheless, in applications like high-performance audio equipment and precision machinery, Teflon PCBs can significantly extend the lifespan of components by minimizing friction-induced damage.

Now you know the basics of Teflon PCBs, it’s time to discuss it’s applications.

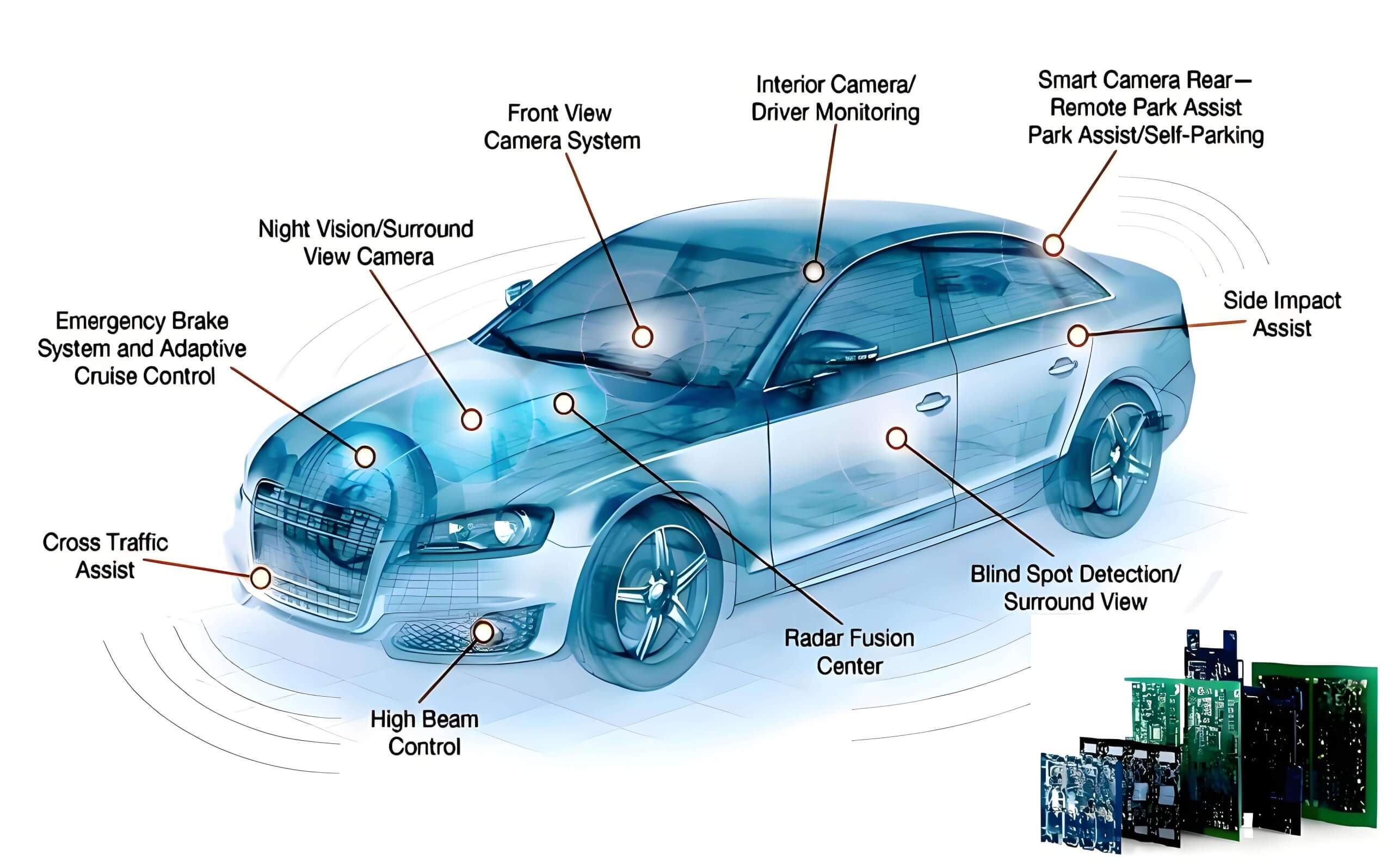

Applications of Teflon PCBs

Teflon-based PCBs have broad applications in all industries as they show characteristics of both good performance and reliability.

- Industrial Control Systems

Teflon PCBs are ideal for use in areas with high exposure to corrosive chemicals, such as chemical processing plants and oil refineries.

Their exceptional chemical resistance ensures uninterrupted operation, making them the preferred choice for critical components in industrial control systems.

- Medical Devices

All this, from deep-brain implants to devices that can be put through hundreds of sterilization cycles, Teflon PCBs will be the “secret sauce” to making medical electronics just as safe and reliable.

They have been of utmost use in the medical field for the reason that harsh chemicals of sterilization do not affect their performances.

- Aerospace and Defense Electronics

In the aerospace and defense sectors, where reliability is non-negotiable, Teflon PCBs shine.

They work in hot temperatures, as well as most hostile chemical environments, which is why they are so common in critical electronic systems, aircraft, spacecraft, and military operations.

- High-Performance Audio Equipment

There might not be copious use of Teflon PCBs for all equipment, or for high-end audio applications, but if the potential exists for improving the signal integrity, why not?

The Teflon PCBs, however, allow for a lower loss and distortion in signals, hence with better sound quality—particularly in audio systems where the coherence of the sound is a requirement.

By now, you must be wondering why Teflon PCB for these applications? Why not other materials PCB can’t be used in these applications? Let’s discuss this in detail.

Teflon PCB vs. Other Materials (FR4, Rogers, Polyimide)

There are different materials PCB being made in the market for different applications according to the output they gave. Here’s an overview of some common materials:

Trade-offs:

- Higher Cost: Teflon PCBs are much more costly than FR4, resulting in less cost-effectiveness for low-budget projects or mass production.

- Machinability Challenges: PTFE has drilling difficulties due to its hardness, and it is not easy to change the shape.

- Limited Electrical Performance: Although Teflon has good electrical properties, it has a relatively low dielectric constant and is not suitable for every high-frequency application. Alternatives, like those in Rogers substrates, may offer some superior performance in specific scenarios, but care would have to be taken based on the specific requirements of the project.

Design Considerations for Teflon PCBs

When designing Teflon PCB layouts, several key factors merit consideration:

1.Manufacturing Challenges

As such, Teflon is hard enough, very strong, and therefore likely to offer many specific difficulties in manufacturing; only precision fabrication can call for unique methods of tools. Engineers should be ready for challenges in drilling and routing.

2.Cost Considerations

Although many of Teflon’s good features are applied to resistance to chemicals and high temperatures, these become costly compared with backbones such as FR-4, and care should be taken regarding such decisions relating to cost. The determination of the designer will have to bear the application of the cost increment justified for Teflon’s unique features.

3.Alternatives for Electrical Performance

The Rogers or Polyimide substrates come into the picture when maintaining high electrical performance and excellence. Their electrical characteristics, concerning improved dielectric loss and superior signal integrity, recommend them highly for service in some high-frequency designs.

Conclusion

In conclusion, Teflon PCBs stand out as a versatile and reliable choice for various electronic applications. Their exceptional properties make them invaluable in industries ranging from industrial control systems to aerospace and defense electronics.

However, there are some specific reasons, including manufacturing challenges and added costs, that may require care in selecting Teflon PCBs. And yet, despite being better than all the rest, Rogers or polyimide substrates would be best for some high-frequency applications on specific occasions.

Every piece of consideration, with all these factors in place, would effectively mean that the designer would have realized the full potential of a Teflon PCB in low cost, superiority, and performance under optimum conditions.