PCB Assembly

in Thailand

Zero defect,

PCB Assembly

Manufacturer

Three Major PCB Assembly Production Bases

We are committed to making our Printed circuit board assembly products zero-defect and can return or exchange them for you without any reason.

Zero defects

We are committed to providing you with zero-defect products.

Trustworthy

In the pursuit of quality, we are always worthy of your trust.

Can be returned or exchanged

No physical objects, no photos, no reason to return or exchange.

Our Clients

Who We Are

We provide the best PCB Assembly Services

Keep Best PCB Assembly Co., Ltd serves many well-known brand customers in industrial control, security, medical, Internet of Things, automotive, artificial intelligence, smart home, power and communications industries at home and abroad.

The company continues to be customer-centric, improves the level of digital intelligence, and is committed to meeting continued high-quality customer needs.

In 2024, we put forward the quality requirements of “zero defects, support for no-reason returns and exchanges” that challenge the limits of the industry, and strive to provide customers and partners with the highest quality products and services in the industry, and assist customers in business success.

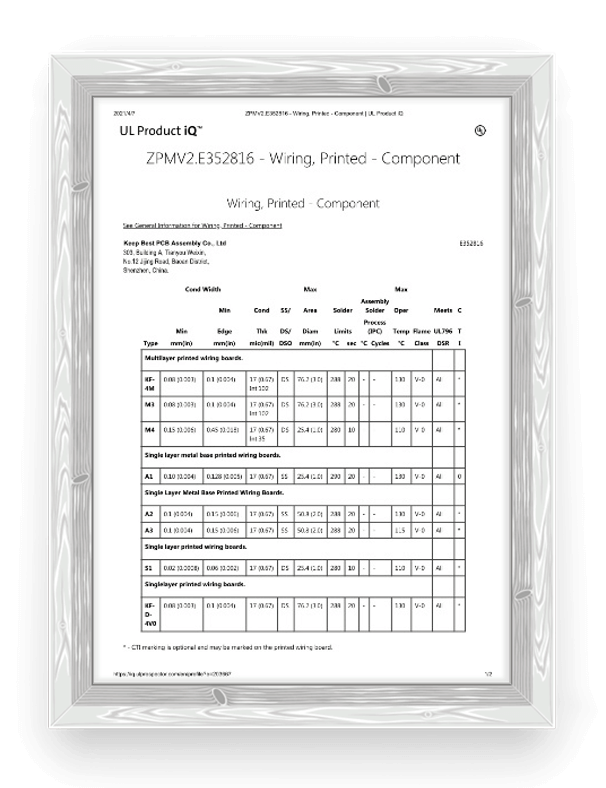

Our Certificates

Over the years, the quality has been affirmed

by customers, in line with all kinds of nationa

export testing, but also through the detection

of some European and American countries.

What We Offer

Full Turnkey PCB Assembly Services

Keep Best PCB Assembly Co., Ltd is a printed circuit board assembly manufacturer integrating component procurement/SMT/DIP/finished product assembly and testing.

PCB Design Service

We have many years of PCB design experience and can meet the various needs of our customers.

PCB DFMA Service

We provide comprehensive DFMA services, including manufacturability analysis, etc.

PCB Manufacturing

We conduct strict quality control on the manufacturing process to ensure product quality.

PCB Assembly Service

We provide one-stop PCBA services, including design, manufacturing, testing and assembly.

Components Purchasing

We have an extensive network of suppliers to ensure you get all the components you need.

Assembly Test

Our assembly testing services cover all aspects to meet your different testing needs.

Machinery and equipment

PCB Assembly Facilities Showcase

Automated Production Line: Features the latest automatic three-proof paint spray and dispensing machines to meet diverse processing needs.

Comprehensive Testing Process: All quick sample products undergo 100% automatic optical inspection (AOI), visual checks, and X-ray testing before shipment.

Applications PCB Assembly Manufactured

PCB assembly and fabrication services for various industries

At our PCB manufacturing company, we take pride in providing high-quality PCB assembly and fabrication services to a wide range of industries. Our state-of-the-art facilities and experienced team allow us to deliver custom PCB solutions that meet the unique needs of each of our customers.

Automobile

PCB Assembly

Medical

PCB Assembly

Industrial Control

PCB Assembly

Internet of Things

PCB Assembly

Internet of Things

PCB Assembly

- Phone:+1 (859) 254-6589

- Email:info@example.com

Testimonials

What Our Customers Are Saying About PCB Assembly Service

Happy to provide great PCB assembly service

Appreciation from delighted customers always motivate us! We have the privilege to work with great clients. Here are some of the words what our clients think! We always approach “Customer First” & deliver the best result! Your business can be the next!

I am very satisfied as a customer of Keepbest Company. Their PCBA products are of excellent quality, with prompt delivery and considerate service, making them a trustworthy partner.

Keep Best has been our trusted PCB and PCBA supplier for over five years. Their products are of exceptional quality, and their customer service is impeccable. We highly recommend them to anyone looking for a reliable and experienced PCB manufacturer.

Keep Best is our go-to PCB and PCBA manufacturer. Their products are top-notch, and their prices are very competitive. We have never had any issues with their products or services, and we are always confident that we can rely on them to deliver high-quality products on time and within budget.

After years of cooperation with Keep Best, we have been deeply impressed by their professional PCB assembly expertise and consistent quality standards. Their products have consistently maintained zero defects (verified by AOI/X-ray inspection), and we are extremely satisfied with their performance.

Keep Best PCBA are offering full-service PCB assemblies from consigned to full turnkey manufacturing, material procurement, assembly, test, system integration, inspection and advanced technologies.

Our staff engineers work with you, our customer, throughout the initial design and development process to ensuremanufacturability, product quality, and consistency.

- PCB Manufacturing

- PCB Assembly

- DFMA Service

- Component Procurement

PCB Assembly Service FAQs

We mainly focus on high-quality PCBA services of "multi-variety, small and medium batches, and short delivery time"

Usually under 100 pieces are classified as low-volume PCB assembly services, which requires a reliable PCB assembler to meet these needs.

Low-volume PCBA assembly can provide high turnaround times without leaving PCBA boards stuck in high unusable inventory.

Yes, we are fully capable of providing PCB manufacturing and PCB assembly capabilities. We have a factory of 50,000 square meters. You can contact us if you need it.

Our estimated delivery times start the day after you place your order, depending on the volume and complexity of your turnkey PCB assembly requirements.

Our Blog

Read our latest blog

What is an SMT Assembly Line?

What is an SMT Assembly Line? This revolutionary technique achieves precise placement of microelectronic components onto printed circuit board surfaces, fundamentally transforming traditional through-hole assembly methodologies. Unlike legacy technologies requiring drilled holes for component insertion, SMT enables significant enhancement of component integration density through its precision mounting capabilities. This advancement drives continuous evolution toward miniaturization and lightweight design in electronic devices. Combined with automated production workflows, such high-density assembly processes empower modern electronics to maintain high performance while achieving superior structural stability and improved manufacturing yield rates. What Equipment is in an SMT Assembly Line? Core Production Equipment Automatic Solder Paste Printer Function: The first critical step in SMT lines, this machine deposits solder paste onto PCB pads using a stainless steel stencil. Precision here directly impacts downstream processes. Technology: Modern printers utilize vision alignment systems for ±25μm repeatability. Key Parameters: Printing speed: 15–30 seconds per board PCB size range: 50×50mm to 510×460mm Pick-and-Place Machine High-speed machines: Optimized for small components (e.g., Yamaha YS series), achieving up to 250,000 CPH (components per hour). Handles 0402 (0.4×0.2mm) to LQFP-208 packages. Universal

A Comprehensive Guide to SMT PCB Assembly

Surface Mount Technology (SMT) is an advanced method in modern electronics production. It uses automated machines to place and solder tiny electronic parts directly onto circuit boards. The key advantage of SMT is its ability to quickly pack components densely onto boards using precise equipment, replacing older through-hole technology (THT) that required drilling holes. What is SMT Assembly? Surface mount technology (SMT) is a method of producing electronic circuits by directly placing components on the surface of circuit boards. SMT assembly emerged as an alternative to through-hole mounting in PCB manufacturing, which peaked in the 1970s-1980s. As electronics manufacturing evolved, more efficient and refined processes became essential. SMT assembly was developed precisely to meet this demand. Advantages of SMT Assembly Space Efficiency and Miniaturization Breakthroughs Achieves 40%-60% volume reduction and 60%-80% weight reduction using miniature components (e.g., 0201, 0402 packages). Smartphone motherboards integrate over 200 solder points per cm², supporting high-density wiring in wearables like smartwatches. Directly enables the slim trend in consumer electronics. Full Automation and Efficiency Leap Automated production: Placement machines handle 50,000 components/hour, reducing labor costs by 50% compared to THT. Improved yield:

Top 15 Best PCB Assembly Manufacturers in the USA

Selecting the right PCB assembly manufacturer is a crucial step in ensuring the successful launch of your product. Keep Best is a fast and reliable PCB assembly manufacturer offering comprehensive services, including component procurement, SMT, DIP, final product assembly, and testing. We guarantee the quality of your products through 19 quality inspection processes—significantly exceeding industry standards—while meeting your fast delivery needs. Get in touch with KEEP BEST To assist you in making an informed decision, here is Keep Best’s list of the top 15 PCB assembly manufacturers in the United States. We’ve outlined their unique capabilities, delivery timelines, and competitive advantages. 1.TTM Technologies Location: Costa Mesa, California Website: ttm.com Company Type: Public Year Founded: 1998 Number of Employees: Approximately 24,000 Key Products: Advanced PCBs, backplane assemblies, RF components Overview: TTM Technologies is a global leader in PCB manufacturing, offering a wide range of products including conventional, high-density interconnect (HDI), flexible, and rigid-flex PCBs. Advantage: Their extensive engineering expertise and broad product portfolio enable them to support complex and high-reliability applications across various industries. Delivery Capabilities and Lead Times: TTM Technologies

What is FR-4

FR-4 Definition FR-4 is a commonly used PCB substrate made from fiberglass and epoxy resin. It is known for its strength, excellent insulation properties, water resistance, and affordability. The name “FR-4” is actually a grade designation that indicates the material has flame-retardant properties. It is widely used in the circuit boards of electronic devices such as computers and smartphones. FAQs What does FR4 stand for? Flame Retardant FR4 is a standard defined by the NEMA (National Electrical Manufacturers Association) for a glass-reinforced epoxy resin laminate. FR stands for “flame retardant” and indicates that the material is compliant with the UL94V-0 standard on plastic material inflammability. *Source:https://www.proto-electronics.com Is FR4 plastic? The designation FR-4 was created by NEMA in 1968. FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. *Source:https://en.wikipedia.org What is the difference between aluminum and FR4? Aluminum PCBs are suitable for applications that require high thermal conductivity and electrical conductivity, while FR4 PCBs are

FR-4 vs. Other PCB Substrate Materials

In the PCB design, manufacturing and assembly process, choosing the right Printed Circuit Board (PCB) substrates is a key decision to ensure performance and longevity in your final product. As we know, the substrate forms the base of the PCB, providing mechanical support and influencing electrical properties. There are the most common substrate material FR-4 and other specialty materials, such as ceramic, aluminum, polyimide, and Rogers,for unique application needs. So,which one should you choose for your products? Hope the following information will be helpful to you. What is FR-4? Here are five grades for FR material: FR-1, FR-2, FR-3, FR-4, and FR-5. The most widely and extensively used material for manufacturing printed circuit boards is FR-4. FR-4 is a glass-reinforced epoxy laminate material known for its durability, moderate cost, and excellent electrical Insulation. Its mechanical strength and cost-effectiveness make it ideal for consumer electronics and generic PCBs. However, while FR-4 is versatile for common applications, but it may not be suitable for high-frequency or heat-sensitive applications, where other materials perform better. Comparison of FR-4 with Other PCB Substrate Materials Choosing the right PCB substrate means understanding the unique properties of each material and comparing them based on

What is Quad Flat Package (QFP)?

Quad Flat Package (QFP) Definition Quad Flat Package (QFP) is a packaging method for electronic components. It has a square shape with numerous thin leads extending from all sides, which can be soldered to a circuit board. Due to the large number of leads, QFP is suitable for connecting complex circuits and is used in devices such as computer processors and TV chips. This packaging type allows for lead pitches of 1.00mm, 0.80mm, 0.65mm, 0.50mm, 0.40mm, and 0.30mm, among others. FAQs What is QFP used for? The QFP is a surface mount integrated circuit package. The standard form is a flat rectangular body, usually square, with leads extending from all four sides. The leads are formed in a gull wing shape to allow solid footing during assembly to a PCB. *Source:https://www.mouser.com What is the difference between QFP and QFN? QFP packages contain leads that extend outwards on all sides in a gull-wing (or L) shape. However, QFN packages have no pin leads, hence the name (no-lead package). Instead, they contain metalized contacts on the underside. *Source:https://www.ourpcb.com What are the different types