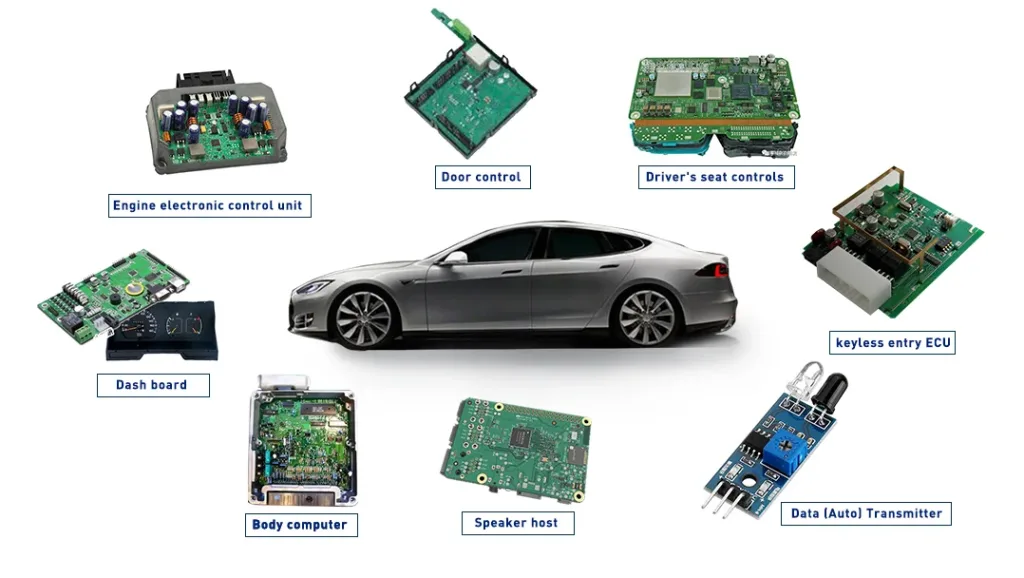

What is Automotive PCB Assembly?

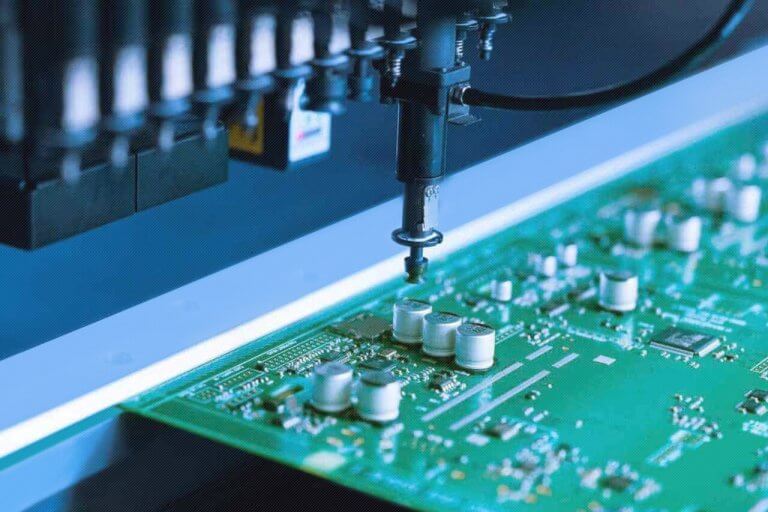

Automotive PCB Assembly (PCBA) is a complex process. In this process, electronic components are put or fixed onto a bare Printed Circuit Board (PCB) that is specially made for vehicles. It is not just about soldering parts. It is a very careful and precise work that turns an empty board into a working electronic brain. This process has several important steps. First, the PCB is made. Then, components are accurately placed using technologies like Surface Mount Technology (SMT) and Through – Hole Technology (THT). Finally, there is soldering, cleaning, and strict testing.

PCB assembly is one of the most difficult parts of electronics manufacturing. In this part, components are firmly attached to the board. The aim is to make a strong and reliable electronic module that can do specific jobs in the tough automotive environment. It helps with standard assembly and allows for automated, large – scale mass production.

How Do Key Challenges Affect Automotive PCB Assembly?

What are the Main Challenges in Automotive PCB Assembly and How to Overcome Them?

There are unique problems in achieving perfect automotive PCB assembly. Dealing with these needs a mix of advanced technology, careful processes, and a strong focus on quality. The automotive industry expects nothing but the best because the risks—like vehicle safety and reliability—are very high.

High Reliability and Low DPPM Demands

Automotive applications demand near-zero failure rates, often measured in Defective Parts Per Million (DPPM). This extreme reliability requirement is a constant pressure.

Overcoming the Challenge: Achieving this involves a multi-pronged approach:

- Rigorous Process Control: Implementing strict statistical process control (SPC) to monitor and refine every stage of assembly.

- Advanced Testing: Employing “secondary testing” methods to catch defects like high-voltage breakdowns that initial tests might miss, and using higher test parameters (voltage, thresholds) to detect subtle flaws.

- Error-Proofing Systems: Utilizing systems like “good board marking” and “bad board error-proofing boxes” to prevent human error and mix-ups.

- Equipment Calibration: Regularly calibrating test machinery to ensure consistent and accurate results.

Harsh Operating Environments

Automotive PCBs are subjected to a brutal gauntlet of conditions: extreme temperature fluctuations (-40°C to 125°C or higher), high humidity, corrosive agents (road salt, fluids), constant vibration, and significant electromagnetic interference (EMI).

Overcoming the Challenge:

- Material Selection: Choosing robust PCB materials like high-Tg FR-4, or specialized substrates such as aluminum for superior heat dissipation in power electronics.

- Design for Environment: Incorporating thermal management features (thermal vias, heatsinks), EMI shielding, and robust mechanical mounting.

- Conformal Coating: Applying protective coatings to shield the assembly from moisture, dust, and chemicals.

- Component Selection: Using automotive-grade components (AEC-Q100/Q200 qualified) designed to withstand these stresses.

Miniaturization and Increasing Complexity

Modern vehicles are packed with electronics, leading to a demand for smaller, lighter, and more densely populated PCBs. This often involves High-Density Interconnect (HDI) technology, finer pitch components, and complex multi-layer boards.

Overcoming the Challenge:

- Advanced Assembly Technologies: Utilizing state-of-the-art SMT equipment capable of handling fine-pitch components and complex packages.

- HDI Expertise: Mastering HDI manufacturing processes, including microvias, laser drilling, and sequential build-up techniques.

- Design for Manufacturability (DFM) & Assembly (DFA): Collaborating closely between design and manufacturing teams to optimize layouts for efficient and defect-free assembly.

- 3D Inspection: Employing 3D Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) to verify component placement and solder paste deposition with high precision.

Soldering and Assembly Defects

The soldering process is critical, and defects such as cold solder joints, solder bridges, voids, lifted pads, and component misalignment can severely impact reliability. Component misalignment can also occur due to issues like insufficient solder paste viscosity.

Overcoming the Challenge:

- Optimized Solder Paste and Application: Careful selection of solder paste and precise control over its application (e.g., stencil printing, jetting).

- Reflow Profile Management: Developing and meticulously controlling reflow soldering temperature profiles to ensure proper solder melt and wetting.

- Flux Management: Using appropriate flux types and ensuring thorough cleaning post-soldering to prevent residue-related issues.

- Skilled Workforce and Automation: Combining the expertise of skilled technicians with the precision of automated placement and soldering equipment.

- Inspection Technologies: Leveraging AOI and Automated X-ray Inspection (AXI) to detect hidden solder defects.

Stringent Testing and Quality Control

Ensuring that every assembled PCB meets the rigorous automotive standards (e.g., IATF 16949) requires a comprehensive and multi-layered testing strategy.

Overcoming the Challenge:

- In-Circuit Testing (ICT): Verifying individual components and circuit continuity after assembly.

- Functional Testing (FCT): Simulating the PCB’s operational environment to ensure it performs its intended functions correctly.

- Environmental Stress Screening (ESS): Subjecting PCBs to temperature cycling, vibration, and humidity tests to weed out latent defects.

- Traceability: Implementing robust traceability systems to track components and processes for every board, facilitating root cause analysis if issues arise.

- Continuous Improvement: Establishing feedback loops from testing back to design and assembly processes to continually enhance quality and yield.