Tired of continuously struggling with the proper implementation of an analog signal using PCB designs? You are not alone. It is tricky to work with continuous voltage or current changes in a circuit and, at the same time, keep that signal clean and free from noise.

Don’t worry, by the end of this article, we will have everything to do with generating an analog signal on a PCB. Here, you will know how to ensure electronic projects work at their best by generating and managing analog signals on your PCB.

Let’s start, then.

Understanding Analog Signals

Analog signals are the continuous changes in terms of voltage or current. Unlike digital signals, which are either high or low, analog signals can have various values within a range set.

Analog signals are, therefore, best adapted to real-world processes like sound, temperature, or light.

However, these high-speed potentials of analog signals are the characteristics which produce a problem in the quality of accuracy and therefore have a high sensitivity to noise.

Importance of PCBs in Analog Signal Generation

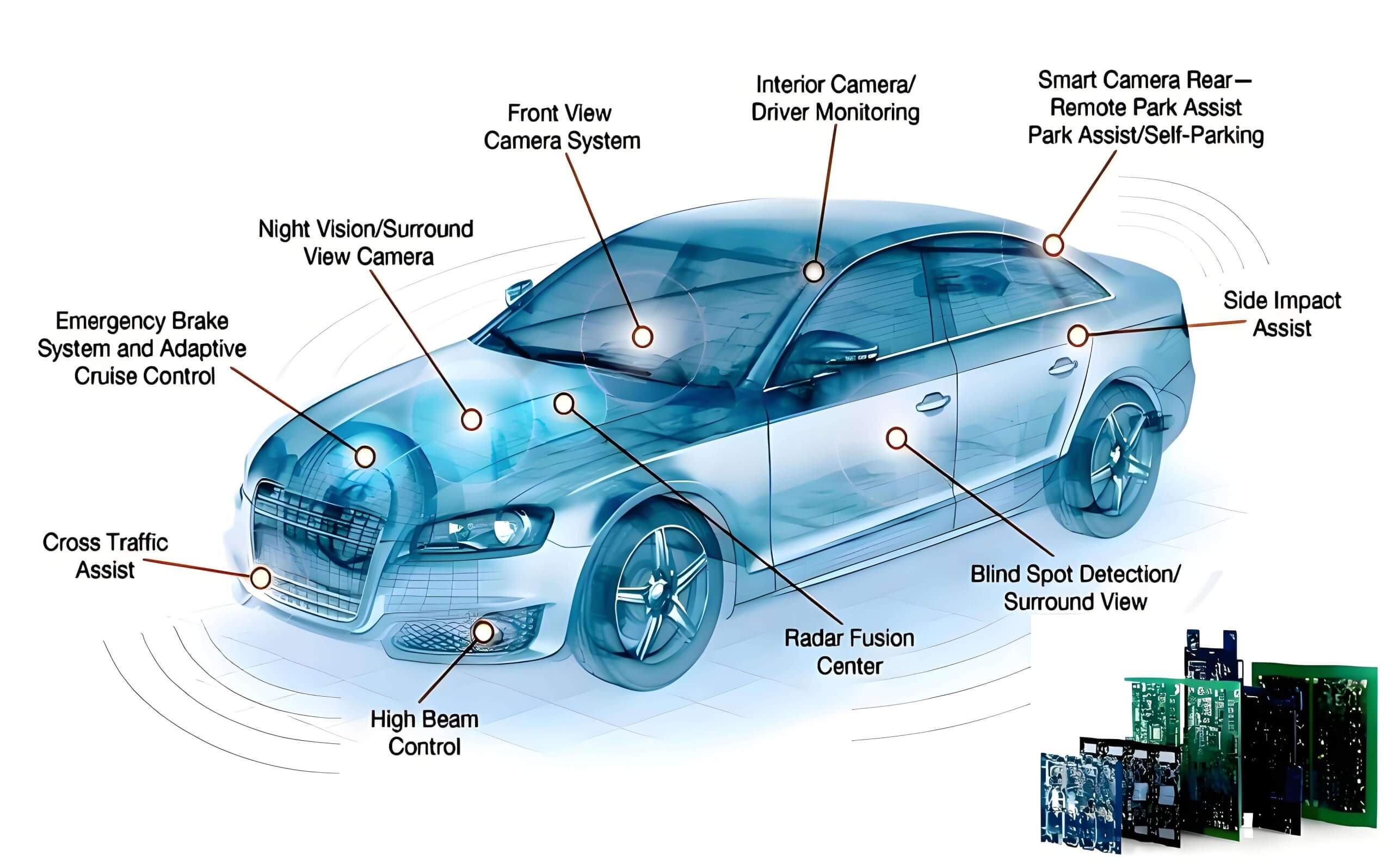

PCBs or Printed Circuit Boards are important in the generation and processing of signals. They are the physical bases where components are inter-connected to get the appropriate signals from the source, then amplify and further process them through associated circuits.

The structure and layout of the interconnect are extremely critical, if not important, for very large areas, allowing signal integrity together with the demanded signal performance to penetrate almost all, if not all, electronic applications, such as audio gadgets and sensor systems.

Now that we have some basics of generating analog signals on a PCB, we can go through the process of design.

Key Design Considerations for PCBs in Analog Signal Generation

The following are the set of key factors necessary to consider while designing PCBs in analog signal generation.

Component Selection

Proper Analog Signal Generation begins with the selection of components, which may include resistors, capacitors, operational amplifiers, among others, corresponding to the desired frequency, amplitude, and stability.

- Resistors and Capacitors:These are elementary components that mold a signal through frequency filtering and amplitude setting. Precision and tolerance are the most important parameters here in terms of signal fidelity.

- Operational Amplifiers:The op-amps amplify the signal with their own characteristics of bandwidth and noise performance, which influence the quality of the signal.

Signal Integrity

Ensure the signal’s integrity to maintain the analog signal’s reliability with respect to noise and distortion, besides proper impedance matching.

- Noise Reduction:Noise suppression aims to reduce electromagnetic interference through shielding and the proper grounding techniques.

- Minimize distortion: Choose only components that have a low rating of distortion and apply clean power supplies.

- Impedance Matching: The impedances of components and their associated traces must be matched to avoid signal reflections and loss.

Circuit Design

The basic information is fundamental for successful signal production because the analog circuit design essentials learn the basics.

- Voltage Dividers: Small voltage scaling circuits.

- RC Filters: These are the filter circuits cutting unwanted frequencies from a circuit, and this is critical for clean signal generation.

- Oscillator Circuits:They produce periodic signals—sine waves or square waves—that are indispensable in most analog applications.

Now, let’s discuss some PCB layout techniques.

PCB Layout Techniques

The PCB layout can largely influence signal integrity and performance.

This is the advice we would like to give you:

- Proper Grounding with Power Plane Design: Use solid ground planes to minimize noise and provide stable reference points of signals.

- Direct Trace Routing: Try to keep traces as direct and short as possible in order to minimize signal losses and delay.

- Minimize Crosstalk: Avoid the agglomeration of digitals and analogs.

- Decoupling Capacitors:These should be placed close to the power pins of ICs in order to filter out noise from the power supply.

Design Process of Analog Signal Generation on PCB

The following steps will guide you on how to understand the design process of analog signal generation on a PCB:

Step #1: Defining Requirements

The first step is to define absolutely what you expect from your analog signal in terms of frequency, amplitude, and waveform type. Being known, such requirements set guidelines upon which both components and circuit design are based.

Step #2: Schematic Capture

Next, sketch out a schematic of your circuit. Use schematic capture software to draw the connections between components – such as resistors, capacitors, and operational amplifiers. Doing this will help you visualize the circuit while making sure all parts are drawn properly.

Step #3: PCB Layout

Translate the schematic into a physical layout of the PCB, placing components in the appropriate points on the board, and routing electrical connections with the help of PCB design software.

For efficient results, the above-given techniques for laying out PCBs must also be followed.

Step #4: Simulation

Simulation tools are often good to use even before making the PCB. Through simulation, one can be able to visualize how the circuit works and areas of potential problems. This step makes it possible to find problems early in the process so as to save time and resources.

Step #5: Production and Test

After finalizing the design and simulation, make sure the results are fine. Move on to PCB manufacturing: after receiving the board, thoroughly check the board to finally meet your requirement, turn it on, and check the characteristics of the output signal to adjust them.

Conclusion

So that’s all about generating the analog signal on PCB. Armed with this knowledge and strategies mentioned in this article, you would be well-armed to take up the challenge of analog signal generation for an assurance of project success.