Full Box Build Assembly

KEEP BEST PCBA Services provide one-stop Box Build assembly which include PCBA assembly,cable assembly,mechanical Assembly,software/firmware Installation,final packaging,logistics.

- Home

- Box Build

Box Build Assembly

Box Build Assembly is a comprehensive service provided by KEEP BEST PCBA that encompasses the final stage of the printed circuit board assembly (PCBA) process. It involves the integration of all the necessary components, sub-assemblies, and wiring into a complete and functioning product. This service is vital for customers who require a ready-to-use and fully tested electronic device, without having to worry about the intricate details of component sourcing, assembly, and testing. With our expertise and state-of-the-art facilities, we meticulously handle the entire box build assembly process, ensuring the highest quality standards are met. From assembling the enclosure, installing the PCB, integrating various sub-assemblies, wiring, and final testing, we take care of every aspect to deliver a finished product that is ready for deployment.

What is Box Build Assembly

Box build assembly, also known as systems integration, encompasses the complete assembly of an electronic product or system. It encompasses the assembly of both the PCBA and the enclosure or “box” in which the final product will be housed. It involves various tasks such as PCB assembly, cable harness assembly, and integration of electrical and pneumatic systems.

Box Build Assembly Service

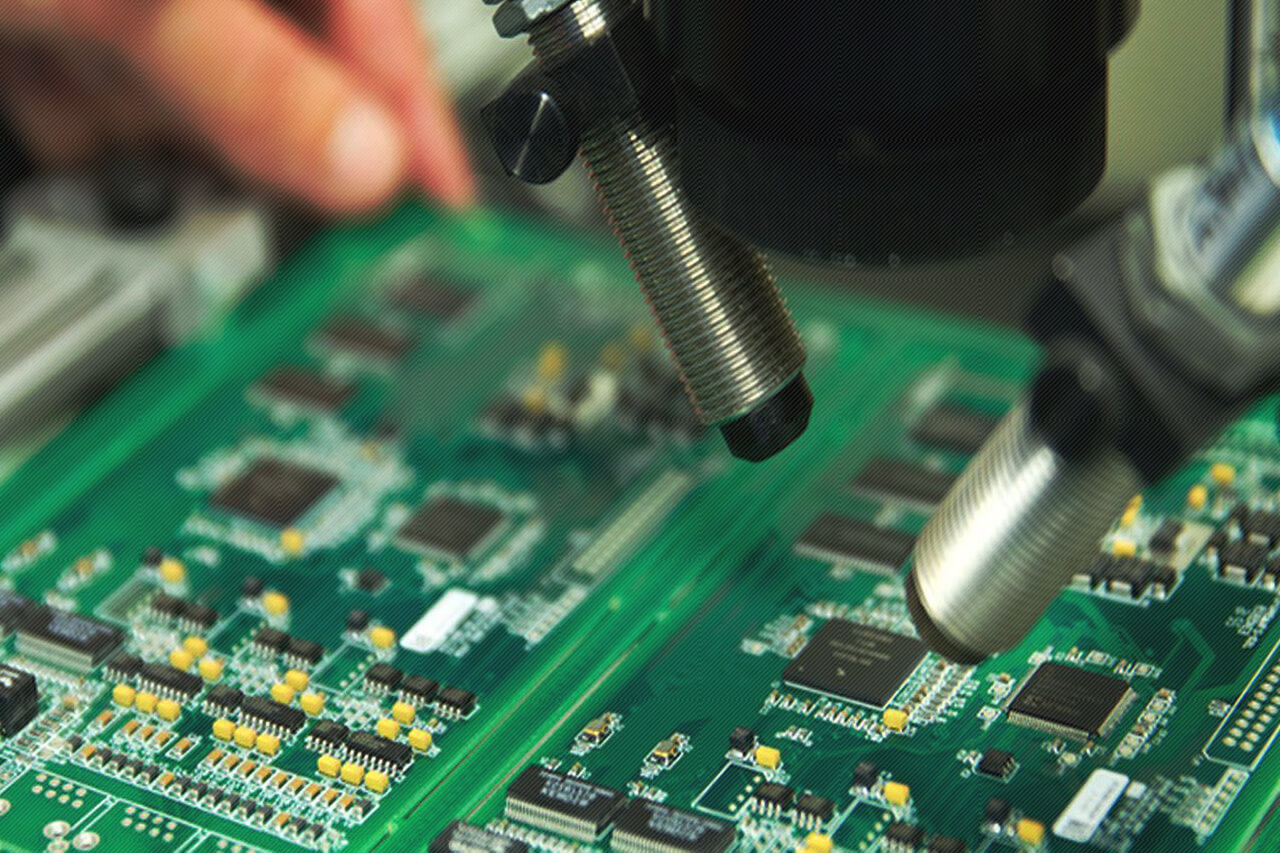

PCB Assembly

The process of populating and soldering components onto the printed circuit board, including both surface-mount technology (SMT) and through-hole components.

Enclosure making

The enclosure not only provides physical protection to the internal components but also serves as an interface for users to interact with the device.

System Level Integration

Integrating mechanical components, such as chassis, enclosures, brackets, fans, and heatsinks, to house and protect the electronics.

Cable Harnessing

Assembling and connecting various cables and wire harnesses to link different components and subsystems within the product.

Software/Firmware Installation

Loading necessary software or firmware onto the system’s microcontrollers or processors.

Testing and Quality Control

Conducting functional testing, verification, and quality inspections to ensure the assembled product meets specifications and performance requirements.

Logistics and Fulfillment

Handling inventory management, order fulfillment, and shipping services to deliver the finished products to customers or end-users.

Packaging and Labeling

Properly packaging the finished product for shipping and distribution, including labeling and documentation.

Benefits of Full Box Build Assembly Services

The advantage of opting for a high quality custom-made box build is its tailored approach to meet your unique requirements.

Cost saving

A good build assembly service ensures that its employees understand the testing and installation of different build boxes,guaranteeing efficient and error-free assembly.

By choosing electronic manufacturing services,you can experience cost savings as they can source components in larger quantities, reducing the need for purchasing small lots of wires, connectors, and tie wraps.

Quality Guarantee

With mass-produced items, the materials used may be compromised to cut costs. Opting for a custom build gives you complete control over component quality, ensuring optimal performance, compatibility, and durability. We meticulously document and audit our quality control procedures, ensuring our clients’ satisfaction.

Supply chain simplification

Competent box build assembly services offer valuable expertise, guiding you on design streamlining. By handling the creation or procurement of cables, circuit boards, and chassis, they simplify your supply chain, reducing overall complexity. You can optimize your product’s manufacturing process and ensure a seamless, efficient assembly of the final product.

Applications of Box Build

PCB box build is used in various industries, including

Consumer Electronics

Used in the assembly of smartphones, tablets, laptops, and other consumer electronic devices.

IoT and Wearables

Employed in the assembly of smart home devices, wearables, and IoT devices.

Automotive

Employed in the manufacturing of automotive control systems, infotainment systems, and sensors.

Industrial Automation

Utilized in the assembly of machinery, process control systems, and industrial monitoring devices.

Medical Devices

Applied in the manufacturing of medical equipment and devices for diagnostics and treatment.

Aerospace

Used in avionics, communication systems, and military equipment.

Consider For Box Build Assembly Process

If you’re planning to incorporate a box build assembly process , here are key factors to keep in mind.

Bill of Materials (BOM)

Providing a comprehensive BOM allows EMS suppliers to have a clear understanding of all essential components and materials needed for your project.It’s important to include even smaller items like tie wraps, adhesives, nuts, bolts, heat shrink, washers, and wires .

3D CAD model

providing 3D CAD models is highly beneficial as it allows for a clear visualization of the final product. Numerous CAD systems offer free drawing viewers for this purpose.

Sample Unit / Prototype

Having a sample unit is highly beneficial, especially if your designs are incomplete. It can serve as a valuable source of information and aid in the development of comprehensive plans.

Testing Case

Testing is a critical aspect of box build assembly, and customers should clearly specify the required tests. Safety is paramount in any electrical device, and basic electrical system tests like the earth bond test and flash test are essential.

Product Dimensions

The dimensions of the unit, including size and weight, provide crucial information to the EMS for handling the assembly process effectively.

Packaging and Shipping Info

Providing a clear outline of the final packaging and shipping requirements before starting the production process is essential for efficient planning.